Exquisite Lost Wax Casting Process

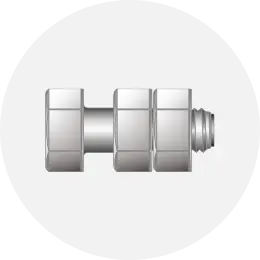

Our company is a long-established steel casting factory in central Taiwan, specializing in stainless steel precision casting and dedicated to delivering high-precision and durable high-quality parts. We mainly produce valve products, which are applied in fluid control with functions such as switching and regulating flow and pressure. Valves come in many types including gate valves, ball valves, needle valves, butterfly valves, check valves, foot valves, and many others. They are further categorized based on application—such as for water, compressed gas, steam, chemical gases, etc.—each fluid requires a suitable valve type.

Our primary production types include investment casting (lost wax casting), centrifugal casting machines, automatic sand casting, and traditional sand casting. Our services include investment casting production, lost wax mold design and development, machining, and customized services based on client needs. We provide integrated design and manufacturing services and focus on ESG practices to ensure product stability and reliability.

-

Step 1: Design & Engineering

Feng Jou uses SolidWorks software to bring your creative designs to life. In addition, with ProCAST software for investment casting analysis, we can effectively eliminate doubts and errors in early-stage development, avoid casting failures, and fine-tune engineering design models to achieve high-quality standards in a cost-effective manner.

-

Step 2: In-House Mold Making

With a skilled team of technicians and engineers, Feng Jou can quickly respond to dimensional and quality issues to meet design requirements. This allows us to identify and resolve any concerns in the mold-making process before production begins.

-

Step 3: Wax Injection

During wax injection, we monitor and control parameters in real-time, improving production efficiency and dimensional stability. Using cooling fixtures ensures the wax parts remain consistent before cooling to room temperature.

-

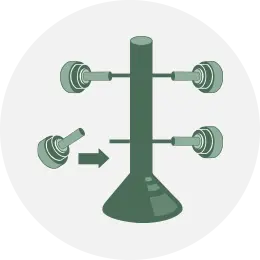

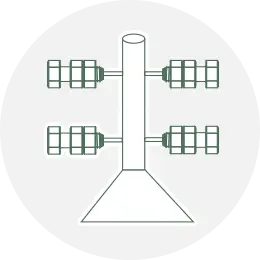

Step 4: Wax Assembly

Wax assembly is a complex process requiring expertise and experience as it directly impacts final casting yield. Our trained technicians manually assemble the wax parts onto the wax tree runners. Once assembled, the trees are cleaned and proceed to the coating process.

-

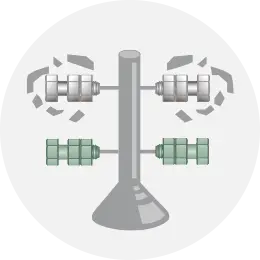

Step 5: Shell Making

Feng Jou uses 6-axis robotic arms on the slurry line to ensure even coating on wax trees, improving consistency. This process is repeated 4–5 times.

To ensure high-quality shells, we monitor temperature and humidity in the shell environment. -

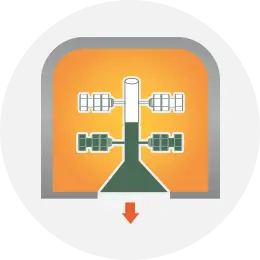

Step 6: Dewaxing

Using high-pressure dewaxing equipment, steam removes wax from the shell. The wax can then be recycled for future production, reducing environmental waste.

-

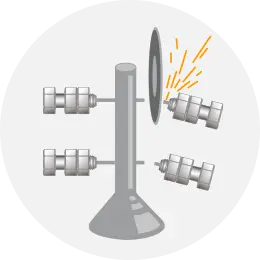

Step 7: Casting

Feng Jou is committed to delivering world-class casting quality. Every batch of molten metal is analyzed with a spectrometer to verify chemical composition. Approved alloys are poured into shells preheated to 1100°C.

-

Step 8: Shell Removal

After the shell cools, we use automatic shell-knocking machines to break and remove the shell material.

-

Step 9: Casting Cutting

Skilled personnel cut castings from the sprue head, separating the parts. To ensure labor safety and cost-efficiency, we use semi-automated operations.

-

Step 10: Shot Peening & Sandblasting

To ensure superior casting quality, we use shot peening to give the surface a bright, uniform satin finish.

For a finer finish, glass bead blasting is applied to enhance surface brightness. -

Step 11: Final Treatment

We employ various final treatments such as grinding, sandblasting, welding, and electroplating.

Feng Jou also offers surface treatments like chrome plating, electrophoresis, painting, passivation, electropolishing, and vibratory polishing, providing customers in all industries with products of exceptional surface quality. -

Step 12: Quality Inspection

To ensure every casting meets customer drawings and quality standards, we perform the following inspections based on product characteristics and precision requirements:

1. Visual inspection: Check for pores, cracks, burrs, or other defects.

2. Dimensional inspection: Use calipers and tools to confirm measurements.

3. Material inspection: Ensure materials meet required specifications. -

Step 13: Post-Processing Support

Feng Jou provides a wide range of surface treatments, heat treatments, and machining services such as chrome plating, zinc plating, nickel plating, electrophoresis, painting, passivation, electropolishing, vibratory polishing, heat treatment, normalization, solution treatment, annealing, and CNC machining. We are committed to delivering excellent surface quality to clients across various industries.

-

Step 14: Packaging & Shipping

After completing all inspections and post-processing, Feng Jou provides professional packaging tailored to customer requirements, ensuring castings remain undamaged and uncontaminated during transportation. We choose rust prevention, cushioning, and packaging materials based on the casting’s material, size, and quantity, and label them clearly for easy identification and storage.

After packaging, the products are shipped according to the customer’s specified method.